RVNL led rail bridge engineering challenge

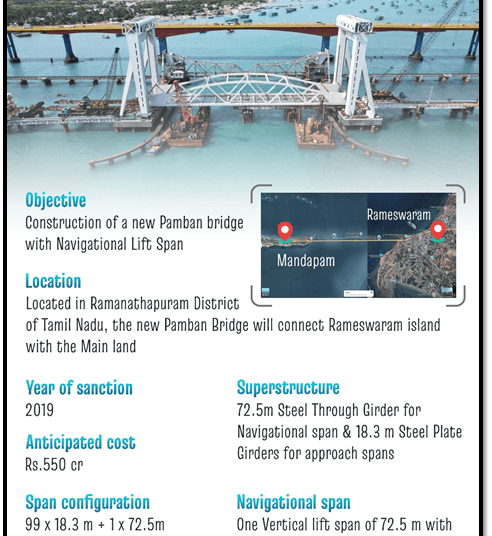

Prime Minister Narendra Modi inaugurated on 6 April the New Pamban Bridge during his visit to Tamil Nadu, a 2.07-km marvel spanning the Palk Strait from the southern Indian state.

It is a first vertical lift railway sea bridge, the Ministry of Railways said.

Rooted in history, its story traces back to 1914 when British engineers constructed the original Pamban Bridge, a cantilever (a long piece of metal or wood that extends from a wall to support the end of a bridge) structure with a Scherzer Rolling Lift span to connect Rameswaram Island with mainland India.

For over a century, it served as a critical lifeline for pilgrims, tourists, and trade. However, the harsh marine environment and growing transportation demands necessitated a modern solution. In 2019, the Government of India sanctioned the construction of a technologically advanced, future-ready replacement https://www.conexpoconagg.com/.

The result is India’s Blending heritage with innovation, the New Pamban Bridge not only preserves the cultural and historical importance of the region but also marks a significant leap forward in design, connectivity, and regional development.

The New Pamban Bridge was constructed by Rail Vikas Nigam Limited (RVNL).

Key Features of the New Pamban Bridge:

The 72.5-meter navigational span can be lifted up to 17 meters, allowing larger ships to pass underneath.

The new bridge is 3 meters higher than the existing one, improving sea connectivity.

The substructure is designed for two tracks, with the superstructure initially accommodating a single line.

The use of modern materials and engineering techniques will ensure the bridge’s longevity.

The bridge has been constructed with stainless steel reinforcement, high-grade protective paint, and fully welded joints.

Special polysiloxane coating protects it from corrosion, ensuring longevity in the harsh marine environment.

By the early 21st century, the old bridge could no longer meet the demands of modern transportation. The increasing volume of traffic, coupled with the need for faster and safer connectivity prompted the government to envision a new structure that would be technologically advanced, durable, and future-ready https://ted.europa.eu/en/.

The construction of a state-of-the-art sea bridge that could accommodate growing traffic volumes, ensure durability and facilitate smoother maritime navigation. The New Pamban Bridge was conceived to address the limitations of its predecessor while paving the way for enhanced regional connectivity and economic growth.

The New Pamban Bridge is set to ensure:

Enhanced Transportation: Accommodating heavier rail traffic and faster trains.

Maritime Integration: Allowing larger vessels to pass without disruptions.

Durability: Ensuring a lifespan of over 100 years with minimal maintenance.

Modern Construction Techniques

The original 1914 bridge was vital for trade and pilgrimage but was no longer suitable for modern rail demands. Given the region’s seismic activity, cyclones, and marine corrosion, a resilient, technologically advanced replacement was essential.

Rail Vikas Nigam Limited (RVNL) led the project, ensuring it met higher speed, load, and maritime requirements. This new bridge enhances connectivity while showcasing India’s infrastructure capabilities in safety, durability, and innovation https://idacexpo.in/.

Selection of Launching Method

Site constraints like limited support structures, low shore draft, ship traffic, fishing activity, and strong sea currents made conventional lift span launching methods unfeasible.

The solution used was pier-to-pier launching of the lift span girder using the ‘Auto Launching Method based on Relationship Principle,’ designed by Suntech Construction Engineering Consultants and verified by IIT Madras.

Transportation, Assembly and Final Welding – After painting and inspection, segments were trucked to Pamban, where a temporary platform with two EOT cranes (Electric Overhead Traveling Cranes) enabled girder assembly. Welding was done in specialized huts, joints inspected by PAUT (Phased Array Ultrasonic Testing), and corrosion protection completed with metalizing and painting https://sbi.com.in/.

Metalizing and painting completed corrosion protection, ensuring structural integrity.

Launching of the Lift Span

Following assembly at Abutment No. 2, the 448.305m lift span was launched in 90 sequences to Pier 77–78 using launching girders and the auto-launching method, with counterweights ensuring precise movement along a 2.65° curve.

Components of the Launching System

Key components included steel stools, stainless steel sliding bases, and swing-type traverse bases with guide rollers. Two front launching girders (51m each) and two rear ones (47m each) were supported at multiple points

Each girder set had ~10 MT counterweights. Tooth plates held jack pistons, and 200T Hilman Rollers enabled smooth movement. Pivots allowed 360° rotation. Push/pull jacks (50T, 1000mm stroke) enabled span movement, requiring 13.375T–18.725T force, factoring lateral resistance https://www.bseindia.com/.

Hydraulic Jacking and Final Placement

Eight 200T hydraulic jacks lifted the span and repositioned the girders.

Mounted on frames at end cross girders, they hung during movement and were supported by adjustable stools at each pier, ensuring precise placement https://www.nseindia.com/.

Lift Span Movement Sequence

With launching girders aligned and span loaded, movement began. Each pier was spaced 20m apart. The 75.70m span required two moves per pier—16m first (rear over pier), then 4m (front over next pier).

Rear and front girders moved in turn to the next piers. This process, repeated over 90 sequences for 448.325m, took 2–3 days per pier. Once at its final position, temporary equipment was removed and the span lowered onto bearings.

Erection of Towers

Towers were fabricated in 28 segments, painted, and transported to Pamban using trailers.

A temporary jetty allowed segments to be loaded onto barges via a 150 MT crane and hauled by boats. A marine crane launched segments near the navigational channel.

Towers were connected by a lintel forming a 21.30m × 6.80m × 4.50m machine room housing the lifting system. The room weighs ~100 MT, with 315 MT counterweights at each end ensuring balance and smooth operation.

Challenges in Construction: Overcoming the Odds

The construction of the new Pamban Bridge presented numerous challenges, ranging from environmental obstacles to logistical complexities. The Palk Strait’s turbulent waters, strong winds, and unpredictable weather patterns created difficulties in the construction process. Additionally, the region’s susceptibility to cyclones and seismic activity necessitated careful planning and robust design.

Another significant challenge was managing logistics, particularly the transportation of heavy materials to the remote construction site. The team had to make the most of the narrow timeframes offered by tidal conditions to ensure timely delivery. Despite these obstacles, the engineers and workers demonstrated remarkable ingenuity, leveraging innovative solutions, advanced technology, and unwavering determination to overcome the difficulties and successfully complete the bridge.

Throughout the execution of the project; which involved over 1,400 tons of fabrication, the launching of lift spans and 99 girders, as well as track and electrification work carried out at sea, the entire operation was completed without a single injury.

India Making its Mark on a Global Scale

While the new Pamban Bridge is India’s first vertical lift sea bridge, it shares similarities with other globally recognized bridges known for their technological advancements and unique designs. These include the Golden Gate Bridge in the United States, Tower Bridge in London and the Oresund Bridge in Denmark-Sweden. Each of these iconic structures, though different in design and functionality, represents a pinnacle of engineering excellence. Now, the new Pamban Bridge stands proudly in their company, combining cutting-edge technology with the challenges posed by India’s coastal and seismic conditions.

The New Pamban Bridge is a symbol of India’s ability to blend tradition with innovation. Overcoming environmental, logistical, and technical challenges, this state-of-the-art vertical lift railway bridge stands as a proud testament to the nation’s growing infrastructure capabilities.

With its modern design, enhanced safety features, and commitment to sustainability, the bridge not only revitalizes a critical transport link but also strengthens regional connectivity and economic development. As trains and ships are all set to pass effortlessly over and under, the bridge serves as a reminder of what can be achieved when vision meets determination. Fiinews.com